The wrong type of glass can put operators at risk and cost businesses money.

But innovations in laminated glass have improved safety and security, minimized exposure to cancer-causing UV rays, improved fuel efficiency and much more.

Here’s a look at six incredible custom laminated glass innovations and how Custom Glass Solutions, the leading manufacturer of laminated glass in North America, helps businesses save time and money while protecting operators.

Laminated glass can help you leave the competition behind when it comes to your professional operators and their deliveries and duties.

How?

By increasing vehicle security, improving operator safety and health, producing energy savings and much more.

Here are the details.

1. Block 99% of UV Rays with Laminated Glass

The American Cancer Society reports “Skin cancer is the most common cancer in the United States. In fact, more skin cancers are diagnosed in the US each year than all other cancers combined.”1

It is estimated that “one in five Americans will develop skin cancer in the course of a lifetime.”2

The FDA has long warned of the risks presented by the sun due to ultraviolet radiation (UV).3 Direct sunlight and tanning bed emission have occupied FDA’s focus and the issue of UV exposure through vehicle glass has rarely been addressed.4

In a 2009 retrospective study of American skin cancer patients, Doctors Butler and Foske concluded that more cases occurred on the left side than the right side of the body and that phenomena was particularly acute in men.5 Several subsequent observations have ratified and refined the conclusions.6

In analyzing the study data, the Skin Cancer Foundation concluded that “[t]he distribution pattern supports the theory that automobile drivers in the US are exposed to more ultraviolet (UV) radiation on the left, through the driver’s side window, and that ultraviolet A (UVA) radiation causes more damage than formerly believed.”7 Up until recently, it was thought that only ultraviolet B (UVB) rays were carcinogenic but recent data now shows otherwise.8

Regular side or door glass, such as tempered glass, blocks UVB rays, but it allows 63% of UVA rays to penetrate the cabin of a given vehicle.9 This suggests that UVA rays may play a more important role in skin cancer than originally thought.10

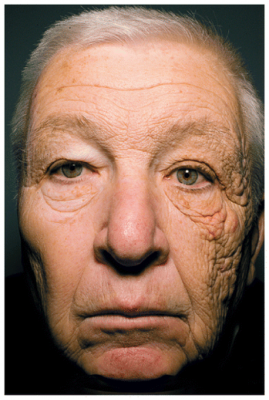

The New England Journal of Medicine displayed the effects of exposure to UV rays with this image of “a 69-year-old man [who] presented with a 25-year history of gradual, asymptomatic thickening and wrinkling of the skin on the left side of his face.”11

The patient had driven a delivery truck for 28 years.12

Findings indicated that his condition was most likely a result of chronic UVA exposure through window glass.13

So how might custom laminated glass help?

FDA has found that sunlight reflecting off of certain surfaces “further increases exposure to UV radiation.”14 As a result, FDA has studied glass and plastic surfaces as a means of protecting the eyes from harmful sun exposure and has determined that certain materials made into sunglasses can provide near 100% UV (both UVA and UVB) protection.15

Similarly, developments in laminated glass manufacturing technology have been able to greatly reduce the transmission of UVB and UVA radiation in occupational vehicles and commercial equipment.16

UV-absorbing additives in the interlayer within laminated glass will block out up to 99% of UVA rays.18

Agricultural equipment, such as tractors or heavy duty construction equipment, do not have federal specifications for glass types or grades and hence rarely are equipped with laminated glass windshields or door glass.18

Workers operating equipment without laminated glass have a level of protection against UVB exposure but have little protection from cancer-causing UVA rays.19

So what can workers at risk for exposure to the sun’s harmful rays do?

FDA recommends that to reduce risks from sun exposure, “people of all colors” should:20

- Limit their time in the sun, especially between 10 a.m. and 2 p.m.21

- Wear clothing to cover skin exposed to the sun;22

- Use broad spectrum sunscreen with an SPF value of 15 or higher.23

Laminated glass is no substitute for FDA guidelines nor has it been evaluated by FDA for efficacy in preventing, mitigating, or treating any disease, including cancer. However, we believe that the scientific evidence suggests that laminated glass may enhance the safety of workers operating equipment and should be seen as an added layer of protection from the sun or in other words, as a supplement to, but not a replacement of, the current FDA guidelines.

2. Save Fuel, Reduce Greenhouse Gas Emissions & Increase Operator Comfort with Solar-Reflective Laminated Glass Coatings

Everyone knows what it is like getting into a car after it has been left in direct sunlight all day.

It is extremely hot!

If it is 80 degrees outside, the interior temperature of an enclosed car can reach over 123 degrees in less than 60 minutes.

Check out this animation developed by General Motors that illustrates the astonishing effects of solar heating.

Here’s why solar heating should concern you: (1) it makes operators uncomfortable and (2) it costs LOTS of money.

Thanks to the common integration of air conditioning systems in occupational vehicle and commercial equipment, operators rarely have to suffer interior vehicle temperatures of over 120 degrees for very long.

However, even with the AC working at full capacity, the interior cabin can reach very uncomfortable temperatures over eight hours of work, especially in direct sunlight.

More needs to be done to keep operators comfortable and productive.

We’ll get to that soon.

Did you know that, every year, commercial vehicles around the world consume billions of gallons of fuel to power their air conditioning systems?

According to the National Renewable Energy Laboratory, light duty vehicles use 7 Billion gallons of fuel per year for air conditioning.

Because operators must constantly run their AC systems to control solar heating, companies are consuming millions of gallons of gas and spending millions of dollars each year.

According to the NREL and EPA, total national fuel savings of 3.7 billion gallons/year could be achieved by 2025 with 30% reduction in air conditioning power.

Plus, most businesses have to replace their AC systems on a yearly basis due to their frequent use.

Reducing the use of AC power will increase the longevity of the system and save money in the long run.

How do you control solar heating while reducing the use of air conditioning power?

Custom laminated glass can help manage solar heating due to innovations in glass technology.

Infrared Reflective (IRR) coatings and PVB interlayers absorb, reflect and block the sun’s rays and significantly reduce solar heating within the cabin.

The latest generations of automotive glass technology can provide over 15% reduction in AC power.

By 2025, that would save over 1.8 billion gallons/year of fuel and reduce carbon dioxide emissions by 2.8 billion kg.

In short, businesses could save millions of dollars by using laminated glass!

And simultaneously help save the environment from CO2 emissions while making operators more comfortable.

3. Reduce Risk of Theft & Decrease Burglary Damage with Security Laminated Glass Innovations

Regardless of the industry (construction, agriculture, commercial transportation, etc.), commercial equipment is expensive and essential to everyday operations.

Theft and/or damages due to an attempted burglary can be very costly due to operational downtime and the need for repairs.

Without laminated glass, commercial equipment is more susceptible to theft and burglary damages.

Laminated glass provides up to 10 times the penetration resistance of conventional tempered glass.

Additionally, glass cutters are made useless due to the plastic interlayer that prevents the two or more layers of glass from being cut.

While custom laminated glass is not always impenetrable, it can protect your commercial vehicle and its content for minutes – long enough to deter most thieves.

Even if a portion of the laminated glass is broken, the plastic interlayer holds the shattered glass together to further impede a burglar’s access to the vehicle and its contents.

Tempered glass, on the other hand, shatters instantly under high levels of impact energy leaving few pieces of glass in the frame.

Check out this video demonstrating how laminated glass and tempered glass hold up against a would-be intruder.

The design and construction of tempered glass unintentionally makes commercial vehicles more susceptible to theft and burglary damage.

Without the proper precautions, an attempted burglary could result in operational downtime and equipment repairs.

To minimize the risk and cost of a potential theft, businesses should consider installing laminated glass on their commercial equipment.

4. Prevent Operator Injury with Improved Custom Laminated Safety Glass Features

Nothing is more important than the safety of your operators when they are on the job.

While certain occupations are more dangerous than others, there is always the possibility of flying debris, the forces of nature (tornados, hurricanes, thunderstorms, etc.) and a commercial equipment crash or accident when you are a professional driver/operator.

During these harmful and potentially deadly situations, operators must be provided with the greatest innovations in safety glass protection.

Unfortunately, many current safety glass applications can unintentionally cause serious or fatal injuries to operators.

Take tempered glass for example.

In the event of a crash, tempered glass provides no protection against passenger ejection.

And flying debris is rarely stopped from entering the operator cab because tempered glass shatters the entire frame of glass when broken.

On the other hand, laminated glass effectively reduces operator injury due to flying debris, glass laceration, or passenger ejection.

The solution they discovered was laminated glass.

According to the National Highway Traffic Safety Administration, impact resistance testing revealed that laminated glazing improved impact resistance by an average of 51mm.

Watch this video demonstrating how laminated glass performs in a hurricane impact test.

While laminated glass can break under immense pressure, the glass fragments remain firmly bonded to the interlayer and, thus, possess increased impact resistance.

This significantly minimizes the risk of operator injury due to falling broken glass.

Better yet… because the entire glass frame is held together by the interlayer, laminated glass reduces the possibility of flying debris entering the cab and prevents passenger ejection.

As a result, car manufactures primarily use laminated glass for windshields.

There is now a movement to use laminated glass for car windows and sunroofs.

Businesses with commercial equipment should follow suit and protect their operators with laminated glass.

5. Benefit from Design Versatility & Save Money on Re-Installations via Custom Laminated Glass

In the long run, laminated glass will save precious time and money for the following reasons:

> Design Versatility

Laminated glazing capabilities have opened up an unlimited number of design possibilities.

Laminated glass can be manufactured flat, curved, annealed, toughened, heat-strengthened, spandrel, wired, tinted, patterned and more.

Moreover, the interlayers can be custom designed with color effects, increased opacity and other designs.

The design versatility of laminated glass allows businesses to find a custom glass solution that meets the unique needs of their commercial equipment and operators.

> Repair Option

Installing glass on commercial equipment is not cheap.

Consider all the costs: the glass product itself, shipping, installation labor, etc.

Now imagine having to paying those costs every time a windshield gets damaged.

As previously discussed, when tempered glass is damaged the entire windshield is compromised, because it instantly shatters every inch of glass within the frame.

By the nature of its design, tempered glass cannot be repaired.

As a result, companies are forced to spend time and money on a replacement product for each windshield that gets damaged, each and every time.

On the other hand, laminated glass can be repaired depending on the extent of the damage and its location on the windshield.

If part of a windshield becomes cracked or shattered due to the impact of debris, a special resin can be injected into the affected area and cured by ultraviolet rays.

6. Reduce Unwanted Noise to Increase Comfort & Productivity with Acoustic-Absorbing Laminated Glass

Commercial equipment often produces a lot of noise, especially in farming, construction equipment, police cruisers and fire trucks.

Significantly reducing undesirable noise within the interior cab can boost productivity, comfort and communication among operators.

Unwanted noise that loudly fills the interior cab can be annoying and distracting to operators.

What if construction operators cannot communicate with their ground workers because the equipment’s cabin is constantly flooded with machine and construction noise?

What if fire and rescue teams struggle to hear each other in the vehicle cab due to their loud sirens?

What if your operators cannot focus because their ears are filled with annoying operational noises for eight hours every day?

What if combine operators want to pass the time away with some music but only hear the loud hum of the engine?

The human ear is most sensitive to sounds in the 1000-5000Hz range.

Acoustic custom laminated glass seeks to absorb these frequencies and increase human hearing within the operator cab.

Constructed using two thin annealed glass panels with a special, sound deadening PVB interlayer, acoustic glass reduces unwanted noise up to 6dB.

By reducing annoying and distracting sounds with laminated glass, businesses can boost productivity because operators are more comfortable and can easily communicate with each other.

Let’s Do a Quick Recap on Laminated-Glass Value…

Custom laminated glass has a lot to offer businesses and its operators.

Here are the highlights:

- Health – Block 99% of UVA Rays and Reduce the Risks of Sun Exposure via Laminated Glass!

- Energy – Save Millions, Protect the Environment and Increase Operator Comfort through Laminated Glass!

- Security – Reduce the Risk of Theft and Burglary Damage by using Laminated Glass!

- Safety – Prevent Serious or Fatal Operator Injuries Thanks to Laminated Glass!

- Versatility & Repair – Endless Design Possibilities and Save Money on Re-Installations

- Sound – Reduce Unwanted Noise to Increase Operator Comfort and Productivity via Laminated Glass!

Laminated glass innovations can save lives, fuel, money, the environment and so much more.

And who gets to benefit from it all?

You, your business and your operators.

The laminated glass market is only going to grow in the years to come.

So join the millions of companies, operators and end-users that are benefiting from these incredible innovations in laminated glass.

Get Started with Custom Glass Solutions by Guardian!

If you are looking to take advantage of laminated glass technologies and innovations, you should choose to work with Custom Glass Solutions.

We are a leading manufacturer of large-format laminated glass in North America.

We manage volumes of over 100,000 parts per year to meet the glass needs of diverse transportation segments such as commercial & public transportation, construction & agriculture, safety & protection, lifestyle vehicles and more.

Each industry and every business has its own unique challenges and goals.

Whether your project is small and flat, large and bent or something in between, Guardian has a custom glass solution for you.

We specialize in custom laminating glass, but our advanced engineering support team is capable of tempering, encapsulating and bending glass. You can learn more about our capabilities.

The benefits of laminated glass are only as good as the manufacturer itself.

Why not work with the best in the business?

We can help your business protect your employees and save money.

Contact us for more information and pricing on CGS laminated glass products. We look forward to speaking with you!

Footnotes:

[1] https://www.cancer.org/cancer/skin-cancer/prevention-and-early-detection.html . The Skin Cancer Foundation reports skin cancer is now the most prevalent form of cancer in the United States. See Sun and Skin News, Skin Cancer Foundation, Dec. 2017 athttps://www.skincancer.org/.

[2] Sun and Skin News, Skin Cancer Foundation, Dec. 2017 at https://www.skincancer.org/ .

[3] https://www.fda.gov/ForConsumers/ConsumerUpdates/ucm049090.htm (“Exposure to the sun can cause sunburn, skin aging (such as skin spots, wrinkles, or “leathery skin”), eye damage, and skin cancer, the most common of all cancers.”)

[4] Id.

[5] Butler, S. T. and Fosko, S. W., Increased prevalence of left-sided skin cancers, J. Amer. Academy of Dermatology, V. 63 Issue 6 at 1006 – 1010, Dec. 2010.

[6] See e.g. Bulliard, J-L & Levi, F. Left-sided excess of melanoma occurrence but not of other skin cancers: Additional evidence, J. Amer. Academy of Dermatology, V. 65 Issue 1 at 206 – 207, July 2011 (reporting that an astonishing 74% of melanoma in situ cases showed left side bias); ; Foske, S. W. , Butler, S. T., Armbrecht, E. S. , Left-sided skin cancer: Importance of age, gender, body site, and tumor subtype in studying skin cancer laterality and implications for future research and public health interventions, Id. at 208 – 210.

[7] Skin & Sun News, Skin Cancer Foundation, V. 27, No. 2, Summer 2010 at https://www.skincancer.org/publications/sun-and-skin-news/summer-2010-27-2/driving-linked . Interestingly in a study similarly conducted in Australia, there was a right-side prevalence but Australian drivers are located on the right side of the vehicle.

[8] https://www.skincancer.org/prevention/uva-and-uvb (“UVA, which penetrates the skin more deeply than UVB, has long been known to play a major part in skin aging and wrinkling (photo-aging), but until recently scientists believed it did not cause significant damage in areas of the epidermis (outermost skin layer) where most skin cancers occur. Studies over the past two decades, however, show that UVA damages skin cells called keratinocytes in the basal layer of the epidermis, where most skin cancers occur. (Basal and squamous cells are types of keratinocytes.) UVA contributes to and may even initiate the development of skin cancers.”).

[9] Sun and Skin News, Skin Cancer Foundation, Dec. 2017 at https://www.skincancer.org/

[10] Id. (“Since glass effectively blocks UVB while cars’ side windows allow 63 percent of UVA to penetrate, “These [new] results may suggest that perhaps UVA plays a more important role in skin cancer development than previously thought,” said Susan T. Butler, MD, coauthor of the study.”).

[11] Gordon, J. and Brieva, J., Unilateral Dermatoheliosis, N. Engl. J. of Med. 366 e25, Apr. 19, 2012 athttp://www.nejm.org/doi/full/10.1056/NEJMicm1104059#t=article

[12] Id.

[13] Id.

[14] https://www.fda.gov/ForConsumers/ConsumerUpdates/ucm049090.htm

[15] Id.

[16] See Brody J., Protect Yourself: That Old Devil Sun Is Lurking, N. Y. Times, May 22, 2006 (“Laminated glass, made of two pieces of glass with a plastic layer between them, filters out nearly all UV radiation without blocking visible light. It also reduces sound transmission. It is commonly used for automobile windshields and in airports, museums, sound studios, schools, greenhouses and large public arenas.”).

[17] Id. See also Duarte J., Rotter A., Malvestiti, A. Silva, M. The role of glass as a barrier against the transmission of ultraviolet radiation: an experimental study, Photodermatol. Photoimmunol. Photomed. Aug, 25, 2009 at 181-4. https://www.ncbi.nlm.nih.gov/pubmed/19614895. Custom Glass Solutions research on file has demonstrated that its laminated glass blocks 99.9% of UV rays. https://www.guardianglass.com/residential/ResidentialProducts/Laminated/Fade/index.htm.

[18] See e.g. OSHA 1926(a) governing motor vehicles operating at an off-highway jobsite not open to traffic at 1926.601(b)(5) (noting only that “vehicles with cabs shall be equipped with windshields and powered wipers. Cracked and broken glass shall be replaced. Vehicles operating in areas or under conditions that cause fogging or frosting of the windshields shall be equipped with operable defogging or defrosting devices.”). See also generally, http://nasdonline.org/1833/d001777/federal-laws-and-regulations-affecting-farm-safety.html.

[19] See Notes 7, 9, 11-13, Supra.

[20] https://www.fda.gov/ForConsumers/ConsumerUpdates/ucm049090.htm

[21] Id.

[22] Id.

[23] Id.

Resources:

https://www.gminsights.com/industry-analysis/automotive-glass-market

http://www.skincancer.org/skin-cancer-information/skin-cancer-facts

http://www.skincancer.org/publications/sun-and-skin-news/summer-2010-27-2/driving-linked

https://www.nrel.gov/transportation/assets/pdfs/fuel_savings_ac.pdf

Worthington, OH 43085

Custom Glass Solutions was formed to meet the manufactured glass needs of diverse industries from Construction and Public Transportation and Military and Civilian Vehicles to Lifestyle Vehicles, and Office / Retail / Hospitality & Industry. Whether it’s small and flat, large and bent or something in between, CGS has the custom glass solution for your commercial and OEM needs. We also offer OEM glass engineering expertise and many glass manufacturing capabilities.

![[CITYPNG.COM]White IG Instagram Insta Text Logo - 3321x995 instagram](https://www.customglasssolutions.com/wp-content/uploads/2021/11/CITYPNG.COMWhite-IG-Instagram-Insta-Text-Logo-3321x995-1.png)